Product design concept and efforts

Our product design adheres to the core philosophy of “safety first, efficiency-oriented, scenario adaptation and green innovation”. We deeply integrate mining site needs, organizing professional R&D teams to conduct in-depth investigations on complex working conditions such as high altitude, humidity and heavy load. From structural design to material selection, every link is strictly controlled: we adopt ergonomic design to optimize operation convenience, select high-strength wear-resistant materials to extend service life, and integrate intelligent monitoring modules to realize real-time fault early warning. With unremitting efforts in design optimization and technological innovation, we strive to create reliable, efficient and eco-friendly mining equipment that truly matches the actual production needs of customers.

The following are common devices. For less common devices, please contact us for details

Mining equipments

Jaw crusher

The jaw crusher is a core piece of primary and secondary crushing equipment operating on the extrusion-crushing principle. Boasting a simple structure, reliable performance and high crushing strength, it is widely used in mining, metallurgy, building materials and infrastructure sectors, and efficiently processes various high-hardness materials including granite, iron ore and limestone.

Impact crusher

The impact crusher is a core piece of secondary and fine crushing equipment operating on the impact-crushing principle. Boasting a high crushing efficiency, superior finished product shape and flexible adjustment, it is widely used in building materials, mining, infrastructure and solid waste treatment sectors, and efficiently processes materials including limestone, granite and construction waste.

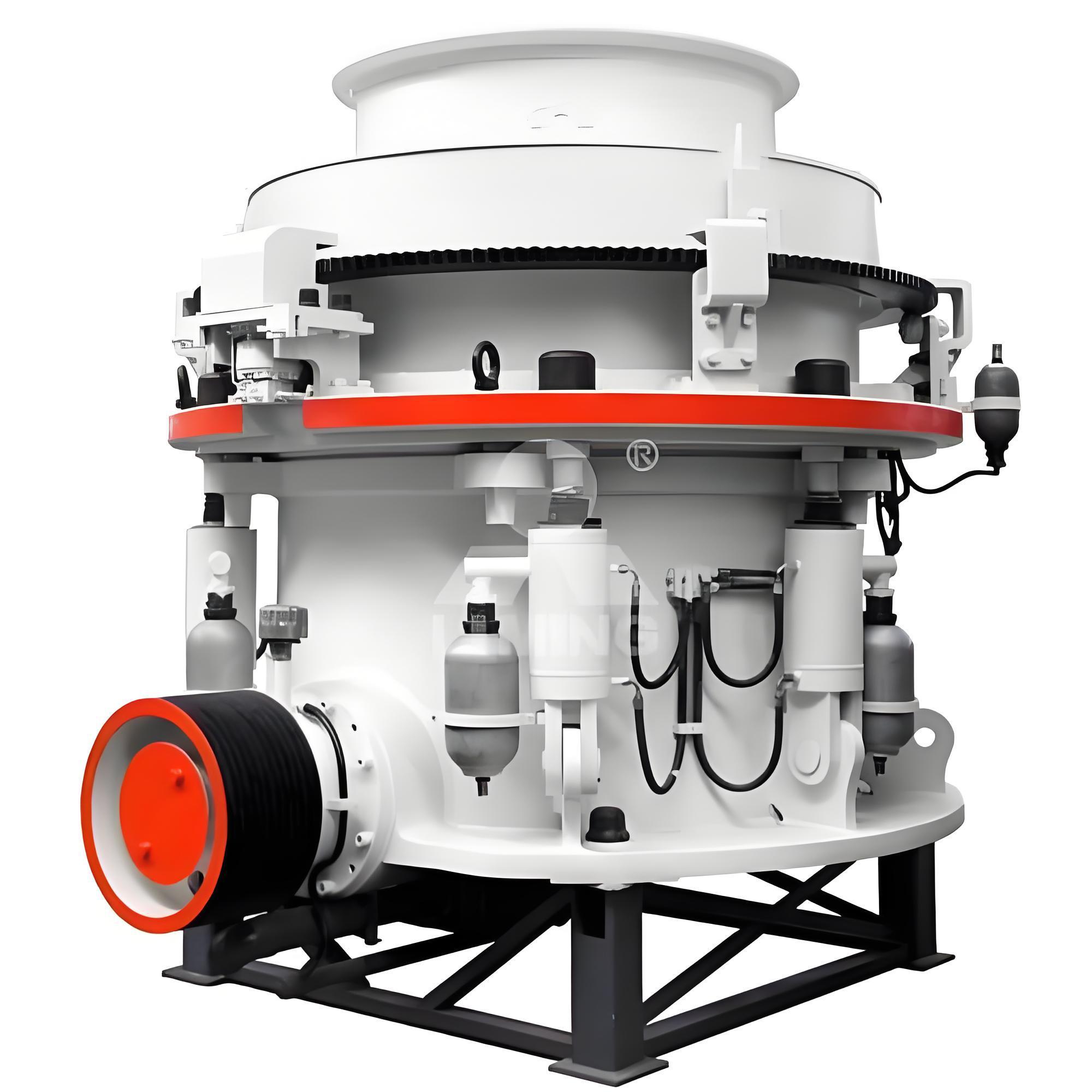

Cone crusher

The cone crusher is a core piece of secondary and fine crushing equipment operating on the layer-compression crushing principle. Boasting a large crushing ratio, precise particle size control and stable operation, it is widely used in metal mining, aggregate processing and metallurgical smelting sectors, and efficiently processes medium-to-high hardness materials including iron ore, copper ore and granite.

Vibrating feeder

The vibrating feeder is a core piece of automated feeding equipment operating on the vibration excitation principle. Boasting uniform feeding, stable operation and convenient adjustment, it is widely used in mining, metallurgy, building materials and aggregate processing sectors, and efficiently conveys materials including ore, sandstone and bulk raw materials.

Vibrating screen

The vibrating screen is a core piece of material sorting equipment operating on the vibration classification principle. Boasting high screening precision, strong processing capacity and easy maintenance, it is widely used in mining, aggregate processing, building materials and metallurgy sectors, and efficiently separates materials of different particle sizes including ore, aggregates and powder.

Mobile crusher

The mobile crushing plant is a core piece of movable crushing equipment operating on an integrated design principle. Boasting flexible relocation, rapid deployment and strong adaptability, it is widely used in mining, construction waste recycling and infrastructure engineering sectors, and efficiently processes materials including ore, concrete waste and sand aggregate.

Metallurgical equipments

Spheroidizing inoculation treatment station

Nodularization and Inoculation Treatment Station Introduction: Key casting equipment for ductile iron production, adopting advanced wire feeding technology. It injects alloy cored wire into molten iron in a sealed environment, improving nodularity and quality. With automatic fume/dust removal (eco-friendly), simple operation, low labor intensity and cost savings, it’s ideal for modern casting enterprises.

WX-6BF Double Stream wire feeder

Dual-stream wire feeder can feed two identical or different wires into ladle simultaneously or sequentially. Equipped with double pinch rolls and intermediate guide rolls, it has upper roll pressed by cylinder, bottom roll driven by motor, and upper roll-linked encoder for precise wire length measurement. The console enables speed setting/display and automatic stop when preset length is reached; forward/backward movement facilitates cored wire assembly/disassembly.

WF-6DT Double Stream wire feeder

WF-6DT dual-stream wire feeder: stepless speed regulation motor with reducer drive, electronic counting & digital display, speed/length setting, electromechanical separation, pneumatic clamping. Enables dual-stream feeding of different wires at varying speeds/lengths/timings or single-stream feeding; full-featured, accurate counting, compact, stable transmission, safe & reliable, ideal for small-scale smelting.

WX-5BF Double Stream wire feeder

WX-5BF variable frequency wire feeder: stepless speed regulation motor direct drive, electronic counting, digital display, speed/length setting, electromechanical separation, manual-pneumatic complementary clamping. Enables dual-stream feeding of different wires at varying speeds/lengths/timings or single-stream feeding; full-featured, accurate counting, compact, stable transmission, safe and reliable, ideal for wire feeding.

5BF Double-stream fully automatic wire feeding machine

5BF dual-stream automatic wire feeder: frequency conversion stepless speed regulation, speed/length setting & display, electronic counting, digital display, PLC control with communication system for central computer networking. Supports local, full-automatic and remote control; motor directly drives rollers, wire fed by pneumatic clamping. Features dual-stream, dual-speed and dual-control (single/double-sided feeding at any speed/length anytime); full-featured, accurate counting, compact, stable transmission, safe & reliable, ideal for secondary refining.

5BFD Single-flow automatic wire feeder

The single-stream automatic wire feeder is a professional equipment for secondary refining. It adopts frequency conversion stepless speed regulation and direct motor drive, with electronic counting, digital display and speed/length setting functions to ensure precise wire feeding. Equipped with a pneumatic clamping mechanism for stable conveying, it supports local and full-automatic control. Compact in size, reliable in operation and accurate in counting, it is widely used in small-scale smelting and metal refining processes for single-type wire feeding.

5BF Double-stream automatic wire feeding machine

Dual-stream automatic wire feeder: high-performance for secondary refining, with frequency conversion stepless speed regulation and direct motor drive. Equipped with dual pinch rolls, pneumatic clamping, electronic counting, digital display and speed/length setting. Supports simultaneous/sequential feeding of same/different wires or single-stream feeding; electromechanical separation, compact, reliable and accurate, suitable for multi-variety precise wire feeding in metal smelting and refining.

5BF Double-stream semi-automatic wire feeder

Dual-stream semi-automatic wire feeder: practical for secondary refining, with stepless speed regulation and motor drive. Equipped with dual pinch rolls, pneumatic clamping, electronic counting and digital display. Supports simultaneous/sequential/single-stream wire feeding (partial manual assistance); compact, accurate, easy to operate, suitable for metal smelting with moderate automation and flexible feeding needs.

5BFB Four-stream variable frequency wire feeder

Four-stream variable frequency wire feeder: high-efficiency for secondary refining, with variable frequency stepless speed regulation and independent stream motor drive. Equipped with 4 sets of pinch rolls, pneumatic clamping, electronic counting, digital display and precise speed/length setting. Supports simultaneous/sequential/single-stream feeding of different wires; electromechanical separation, compact, accurate, reliable, suitable for large-scale metal smelting requiring multi-variety high-precision feeding.

DWX-5BF Casting Special Wire Feeding Machine

The special wire feeder for casting, also known as the spheroidizing wire feeder, continuously injects cored wire containing alloying elements into the bottom of the molten iron ladle through the wire feeder. Due to the action of the high-temperature molten iron, the sheath of the cored wire is melted, and the alloying elements then come into contact with the molten iron, initiating the spheroidizing process.

JBWX-6 type mold feeder

Crystal wire feeder: special for crystal material preparation and metallurgical processes, feeding alloy cored wire accurately/stably into crystallization area. With frequency conversion speed regulation, precise counting, pneumatic clamping/guiding, it enables flexible speed/length setting and smooth conveying. Compact, easy to operate, controls alloy addition, improves crystal purity/performance, suitable for high-precision scenarios like precision casting.

JBWX-5 type mold feeder

Crystal wire feeder: special for crystal material preparation and metallurgical processes, feeding alloy cored wire accurately/stably into crystallization area. With frequency conversion speed regulation, precise counting, pneumatic clamping/guiding, it enables flexible speed/length setting and smooth conveying. Compact, easy to operate, controls alloy addition, improves crystal purity/performance, suitable for high-precision scenarios like precision casting.

Cored wire unit

GBX-6 high-speed alloy cored wire unit

Alloy cored wire units are specialized equipment for producing alloy cored wires by wrapping various alloy powders with cold-rolled strip. Widely used in secondary refining, they effectively adjust molten steel quality, deoxidize and desulfurize. Advanced models (e.g., GBX-6) feature high speed, stable operation, smooth wire appearance and firm edge buckling, favored by manufacturers for reliable performance and cost-effectiveness.

GBX-5 type alloy cored wire unit

The GBX-5 Alloy Cored Wire Unit is a dedicated core device for secondary refining in the metallurgical industry. Designed for the efficient production of alloy cored wires, it is widely suitable for refining needs in steelmaking, casting and other fields.

GBX-5A cored wire machine

GBX-5(A) Cored Wire Machine related products: WX-4BF/WX-5BF dual-stream wire feeders. Direct-driven by stepless speed-regulating motors, they feature electronic counting, digital display, speed-length setting, and electromechanically separated manual-pneumatic clamping. Supporting dual-stream (variable speed/length/time for different wires) or single-stream feeding, these compact, reliable feeders with stable transmission and accurate counting are ideal for wire feeding.

GBX-5S solid core cored wire machine

GBX-5S solid cored wire machine: a dedicated core equipment for metallurgical secondary refining, designed for efficient production of solid cored wires (ideal for cladding pure calcium wire, deoxidized aluminum wire, etc.). Upgraded from traditional powder-filled machines, it solves key technical issues (high-hardness rod feeding, non-circular wire cladding, sealing) and achieves seamless cladding via precise processes like uncoiling, straightening, roller sealing and shaping.

Slag-blocking and dumping vehicle series

DZ-6 type slag-blocking and dumping vehicle

The DZ series slag stopper feeding vehicle is an electromechanical steelmaking equipment used to optimize the converter steelmaking process, improve molten steel quality, and reduce material consumption in subsequent processes. The steelmaking process using the slag stopper can significantly reduce the amount of slag flowing into the ladle during the entire tapping process, thereby obviously improving the quality of molten steel, reducing alloy consumption in subsequent processes, and enhancing economic benefits.

DZ-5 type slag-blocking and dumping vehicle

The DZ series slag stopper feeding vehicle is an electromechanical steelmaking equipment used to optimize the converter steelmaking process, improve molten steel quality, and reduce material consumption in subsequent processes. The steelmaking process using the slag stopper can significantly reduce the amount of slag flowing into the ladle during the entire tapping process, thereby obviously improving the quality of molten steel, reducing alloy consumption in subsequent processes, and enhancing economic benefits.

Spray repair machine series

PB-Y type 0.8(1 ton)

Gunning machine is an indispensable kiln maintenance equipment in high-temperature industrial fields such as metallurgy and building materials, mainly used for lining repair and daily maintenance of high-temperature furnaces like converters, ladles and cement rotary kilns. Its working principle: high-pressure air precisely sprays refractory gunning material onto damaged furnace linings; the material's high-temperature curing forms a dense, wear-resistant refractory layer, quickly repairing damage, extending kiln service life and reducing downtime & maintenance costs.

PB-Y type 1.6(2 tons)

Gunning machine is an indispensable kiln maintenance equipment in high-temperature industrial fields such as metallurgy and building materials, mainly used for lining repair and daily maintenance of high-temperature furnaces like converters, ladles and cement rotary kilns. Its working principle: high-pressure air precisely sprays refractory gunning material onto damaged furnace linings; the material's high-temperature curing forms a dense, wear-resistant refractory layer, quickly repairing damage, extending kiln service life and reducing downtime & maintenance costs.

PB-Y type 2.4(3 tons)

Gunning machine is an indispensable kiln maintenance equipment in high-temperature industrial fields such as metallurgy and building materials, mainly used for lining repair and daily maintenance of high-temperature furnaces like converters, ladles and cement rotary kilns. Its working principle: high-pressure air precisely sprays refractory gunning material onto damaged furnace linings; the material's high-temperature curing forms a dense, wear-resistant refractory layer, quickly repairing damage, extending kiln service life and reducing downtime & maintenance costs.

Business cooperation

If you are interested in our products, please feel free to contact us. Or leave your contact information and we will get in touch with you as soon as possible