Working principle

The core working principle of an impact crusher is impact crushing. It relies on a high-speed rotating rotor driving blow bars to exert violent impact, rebound collision and grinding forces on materials, achieving material crushing and shaping.

- Feeding and Impacting

Materials fall into the crushing chamber from the top feed inlet. The high-speed rotating rotor drives the blow bars to impact the materials at an extremely high linear speed, instantly breaking large materials into small pieces.

- Rebounding and Secondary Crushing

The crushed materials collide with the impact plates on the inner wall of the crushing chamber at high speed. After rebounding, they are impacted by the blow bars again. Meanwhile, the materials collide and rub against each other, forming a cycle of multiple impact-rebound-grinding processes, and are gradually refined to the desired particle size.

- Screening and Discharging

The bottom of the crushing chamber is equipped with grate bars or adjusting plates. Materials that meet the particle size requirements will be discharged through the grate gaps or adjusting clearances; materials that fail to meet the requirements will continue to repeat the crushing process in the chamber until they meet the discharging standards.

Performance advantage

1、High Crushing Force – Featuring a high-strength and heavy-duty rotor design, it boasts large rotational inertia and powerful impact crushing force, making it highly suitable for large-sized material crushing.

2、Dual-purpose functionality – Adjusting the installation position of the impact frame enables switching between primary crushing and secondary/tertiary crushing, achieving dual-purpose operation with a single machine.

3、Hydraulic gap adjustment – The clearance between the impact plate and blow bars is hydraulically adjusted, which is convenient and efficient, enabling precise control over the discharge particle size and ensuring an excellent particle shape.

4、Easy maintenance – The frame can be opened effortlessly, facilitating internal maintenance, inspections and replacement of wear parts.

5、Wider feed inlet – When used as a primary crusher, it can effectively replace the jaw crusher for first-stage crushing, with a maximum feed size of up to 1000 mm.

6、Optimized for construction waste crushing – Its unique rotor design and large-caliber feed inlet effectively prevent steel bar entanglement, avoiding costly downtime and difficult maintenance issues.

7、Long-lasting Blow Bars – Manufactured from premium wear-resistant alloy materials, the blow bars deliver an extended service life, minimizing wear and reducing overall production costs.

8、Optimized Vortex “C”-Shaped Crushing Chamber – The unique vortex “C”-shaped chamber design ensures a more rational material impact angle, boosting crushing efficiency while significantly improving the particle shape and gradation of the finished product.

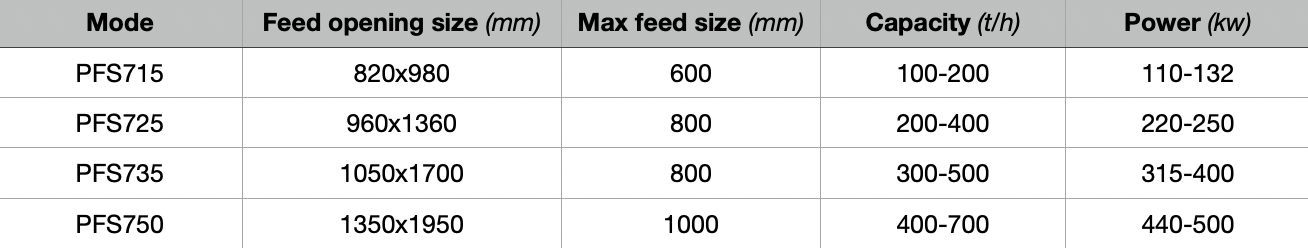

Specification and Performance Parameter table

Specification and performance Parameter Table of European-style impact Crusher

Business cooperation

If you are interested in our products, please feel free to contact us. Or leave your contact information and we will get in touch with you as soon as possible