GBX-6 high-speed alloy cored wire unit

The alloy cored wire machine uses cold-rolled steel strips to wrap silicon-calcium powder, carbon powder, ferrotitanium powder, silicon-aluminum powder, rare earth alloys, etc., to produce alloy cored wires. Applied in secondary refining via wire feeding, it adjusts molten steel quality, realizes deoxidation and desulfurization, etc. Currently, most domestic cored wire machines in China operate at low speed (below 30m/min), with frequent failures and high cost per ton of wire. Based on the wire wrapping principle, our company’s production experience and the advantages of various domestic machines in operation, we have fully redesigned the cored wire machine and developed the GBX-6 Alloy Cored Wire Unit. Featuring high speed, smooth cored wire surface, firm edge crimping and stable mechanical performance, this unit has been highly praised by many users.

Advantages of Hezhong GBX-6 High-Speed Cored Wire Unit Developed by Zhengzhou Hezhong Cored Wire Machinery, the solid cored wire unit is upgraded from traditional powder-filled cored wire machines. Through long-term research, experiments and field tests, it solves key technical problems such as feeding solid metal rods with high hardness, wrapping and sealing non-circular section wires. The GBX-6 High-Speed Cored Wire Unit can wrap both pure calcium wire and deoxidized aluminum wire. Feedback from our existing customers shows that all have achieved satisfactory results and given consistent praise.

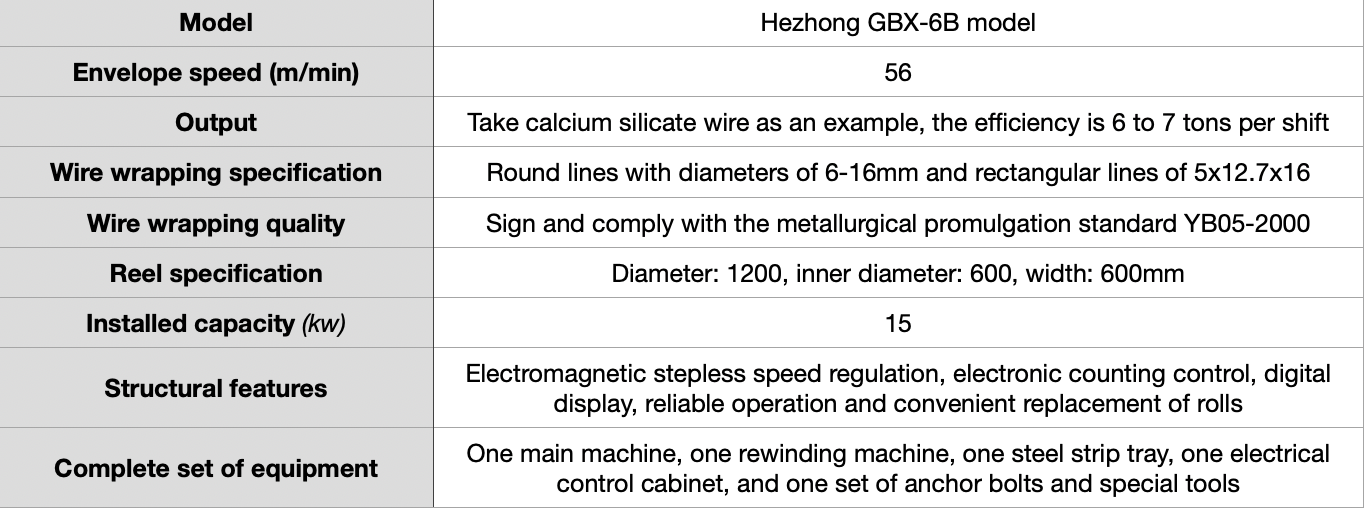

Technical parameters