Working principle

- Feeding and DistributionMaterials are fed into the crushing cavity from the top inlet and evenly distributed on the surface of the mantle by the distributor, ensuring that materials enter the crushing zone uniformly.

- Eccentric Squeezing and CrushingDriven by the transmission device, the main shaft performs high-speed eccentric rotation, which drives the mantle to swing periodically close to and away from the fixed concave. When the mantle approaches the concave, materials in the cavity are squeezed, crushed and ground; when the mantle moves away, the crushed materials fall downward under gravity.

- Layered Refinement and ScreeningMaterials that do not meet the particle size requirements will stay in the crushing cavity and undergo repeated squeezing and grinding with the next cycle of the mantle’s movement. This layered crushing process ensures that the materials are fully refined.

- DischargingMaterials that reach the required particle size will continuously pass through the gap between the mantle and concave (discharge opening) and be discharged from the bottom of the equipment.

Performance advantage

1、Fixed Main Shaft Design – Featuring a fixed main shaft, the equipment boasts strong load-bearing capacity, a more compact structure, small footprint and high efficiency.

2、Intergranular Lamination Crushing Principle – Designed based on the intergranular lamination principle, it utilizes mutual extrusion between materials to significantly enhance crushing efficiency and the proportion of fine materials, while greatly reducing needle-shaped and flaky particles and lowering the steel consumption of wear parts.

3、Advanced Bearing Design – Adopting a tin bronze bushing sliding bearing design, compared with rolling bearings, the equipment can maintain ultra-high load-bearing capacity even in high-dust and high-impact environments, with lower production costs.

4、Reliable Operation Guarantee & Stable Transmission System – A temperature sensor is installed at the oil return port of the horizontal shaft to accurately detect oil temperature and ensure stable operation of the equipment. The transmission system adopts spiral bevel gears, featuring reliable and smooth transmission, low noise and long service life.

5、Enhanced Cone Wall & Improved Liner Fixing – While the cone wall is thickened, the liner fixing method has been upgraded, eliminating the need for potting adhesive. This enables extremely convenient and quick replacement, effectively reducing maintenance costs.

6、Integrated Hydraulic Lubrication – The unique thin oil lubrication system design greatly extends the equipment’s service life. High-performance

non-contact labyrinth seals are more conducive to ensuring the cleanliness of the lubricating oil.

7、Safe Bumper Oil Circuit – The bumper oil circuit adopts large-diameter oil pipes and large-capacity accumulators, featuring better buffering

performance, faster response and higher equipment safety.

8、Standard Floating Mounting Base – Equipped with a standard floating mounting base, it enables simple installation, saving effort and time. It lowers

requirements on the foundation and reduces user investment.

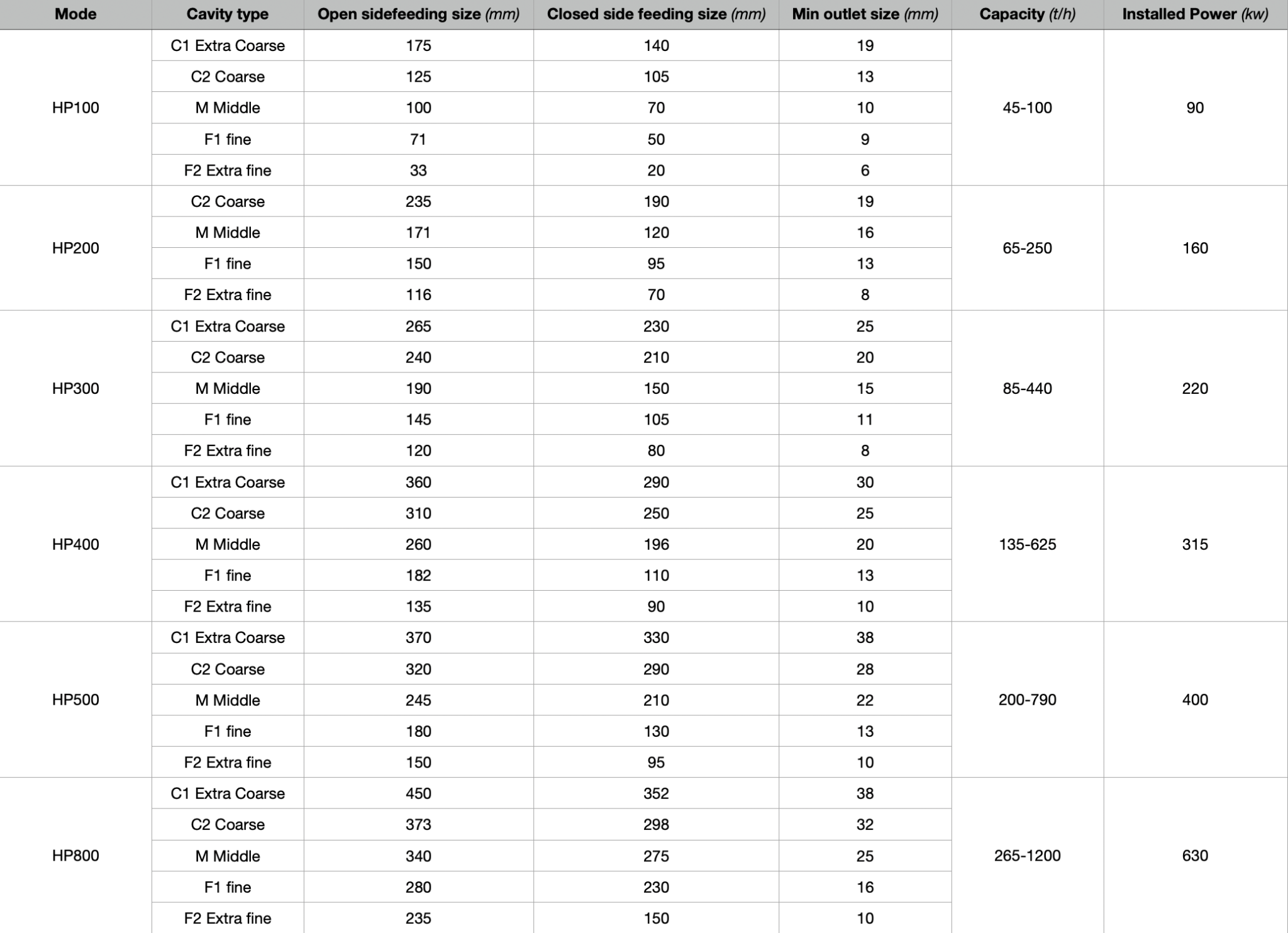

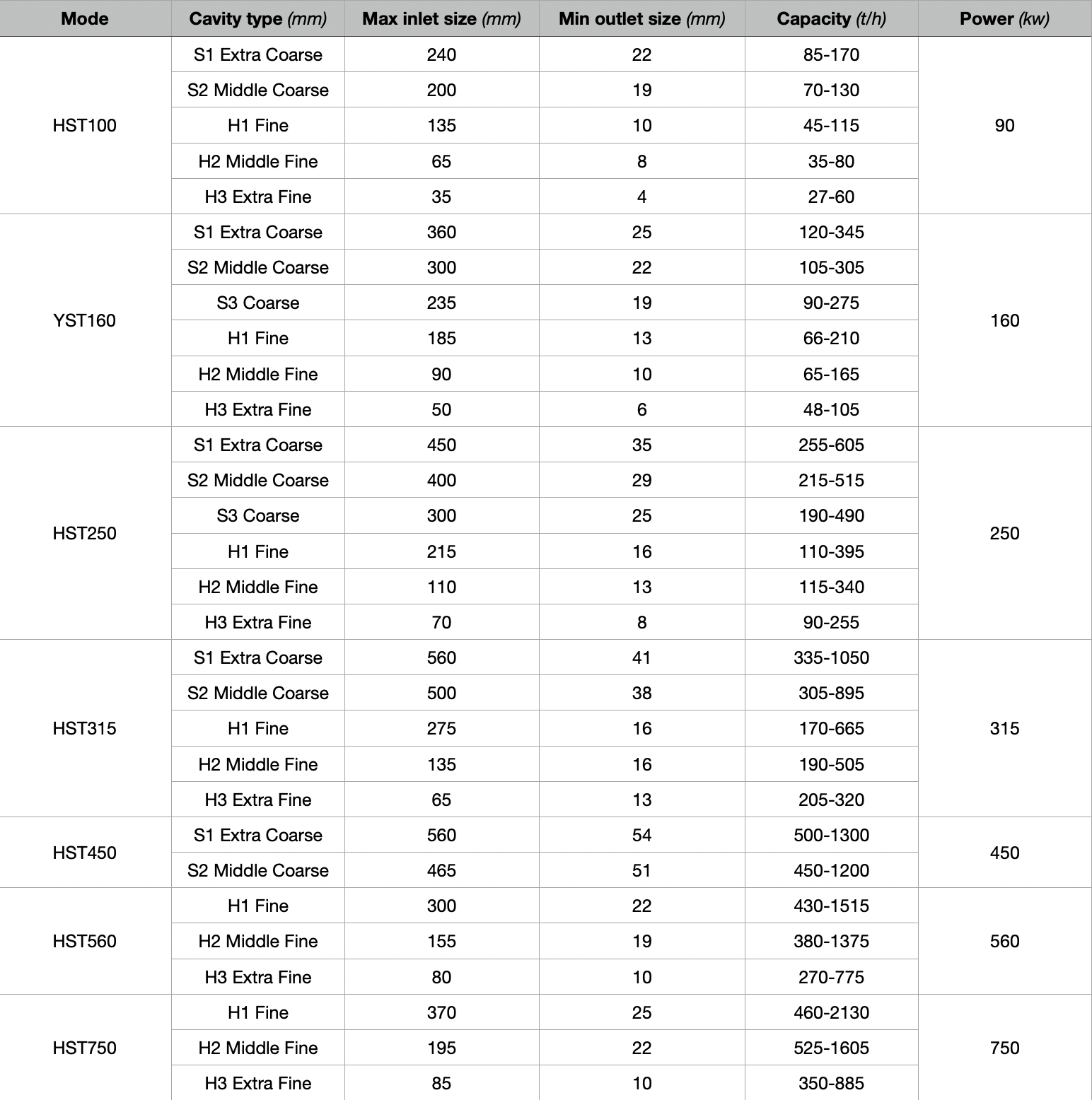

Specification and Performance Parameter table

Multi-cylinder

Single cylinder

Business cooperation

If you are interested in our products, please feel free to contact us. Or leave your contact information and we will get in touch with you as soon as possible