Working principle

The core working principle of the jaw crusher is extrusion crushing. It relies on the periodic reciprocating swing of the movable jaw to apply squeezing force and splitting force to the materials entering the crushing chamber to complete the crushing.

The specific process is divided into three steps:

Feeding and squeezing: Materials fall into the crushing chamber between the fixed jaw plate (static jaw) and the movable jaw plate (movable jaw) from the upper feeding port. The motor drives the eccentric shaft to rotate, bringing the movable jaw close to the static jaw and exerting a strong squeezing and splitting effect on the material inside the cavity.

Unloading: When the eccentric shaft drives the movable jaw away from the static jaw, the space in the crushing chamber expands. The material that has been crushed to the set particle size is discharged from the lower discharge port under the action of gravity.

Cyclic operation: The eccentric shaft rotates continuously, and the movable jaw performs continuous “approaching – moving away” reciprocating motion, achieving a continuous feeding → extrusion crushing → unloading cycle of materials, thus completing large-scale crushing operations.

Performance advantage

1、Deep Crushing Chamber with No Dead Zones – The deep crushing chamber design eliminates dead zones, significantly enhancing feeding capacity and overall output.

2、High Crushing Ratio & Uniform Product Gradation – It features a large crushing ratio, ensuring uniform particle size of the finished product.

3、Gasket-Type Discharge Opening Adjustment – The gasket-type discharge opening adjustment device is reliable and easy to operate, with a wide adjustment range, enhancing the equipment’s flexibility.

4、Reliable Lubrication System – The lubrication system is safe and reliable, with easy component replacement and minimal maintenance workload.

5、Simple Structure, Reliable Operation & Low Operating Costs – Boasting a simple structure, it operates reliably with low operating costs, delivering excellent cost-effectiveness for long-term operations.

6、Energy-Efficient Performance – The equipment is highly energy-saving, achieving 15% ~ 30% energy saving for a single unit and more than double energy saving for the whole system.

7、Wide Discharge Opening Adjustment Range – It offers a broad adjustment range for the discharge opening, catering to the diverse requirements of different users.

8、Low Noise & Minimal Dust Emission – The equipment operates with low noise levels and minimal dust, meeting strict environmental standards for eco-friendly production.

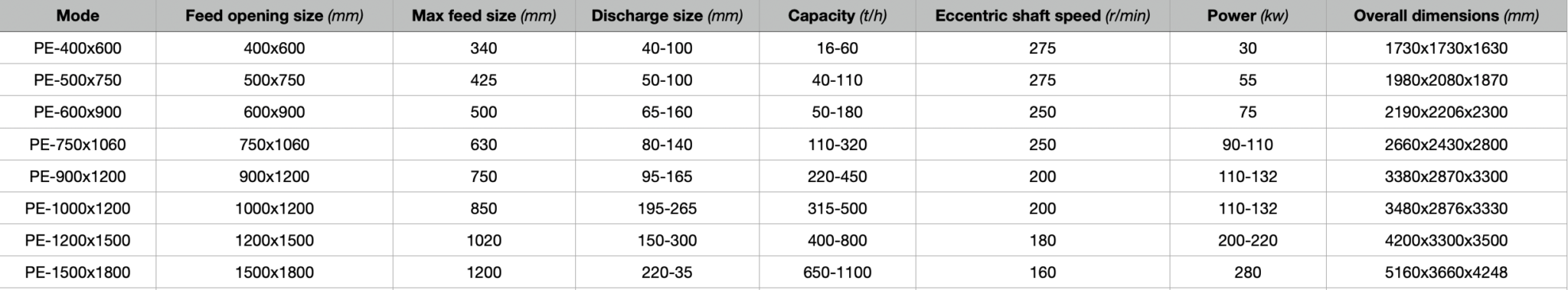

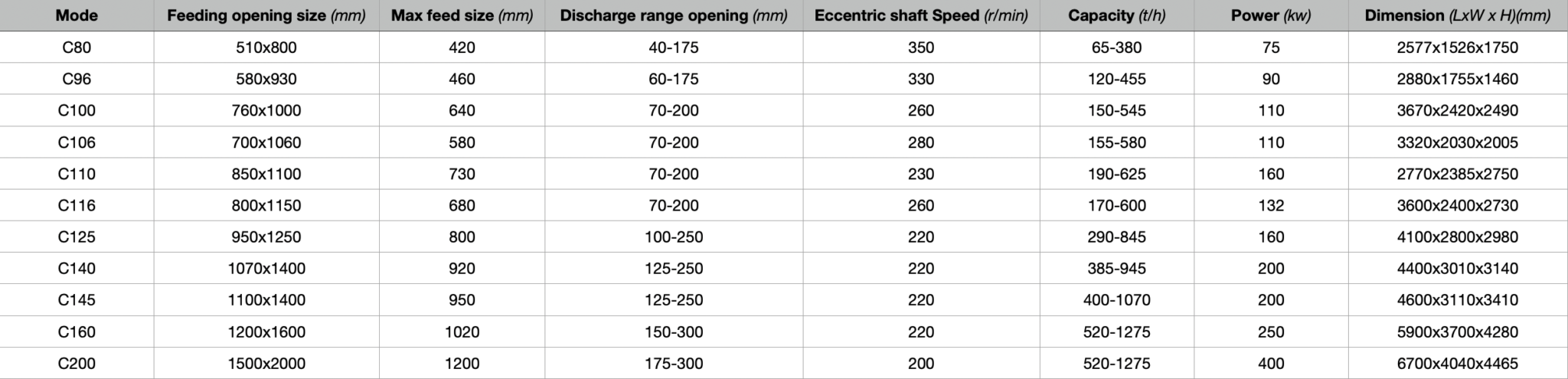

Specification and Performance Parameter table

Business cooperation

If you are interested in our products, please feel free to contact us. Or leave your contact information and we will get in touch with you as soon as possible